Laminates: Installation Instructions

- Impressive Ultra

- Majestic

- Eligna

- Classic

- Impressive

- Perspective Nature

IMPORTANT INFORMATION: It is strongly recommended that these instructions are read in full prior to commencing any flooring installation. Of course, if there are any questions at all or you are unsure about any aspect of the preparation, installation, finishing or maintenance of your new floor, please contact your place of purchase for clarification prior to commencement. Failure to follow these instructions may affect the performance of and/or the warranty on your new floor. If you are reading a printed version of these instructions, please know that things change from time to time and that the latest version of this post will be found at www.sunfloors.com.au

GENERAL INFORMATION: Sun Floors Laminate floors are made using carefully screened raw materials, engineered to provide a high quality laminate floor that is designed to stand the test of time. The patented Uniclic joining system provides for fast, easy and strong floating installations, achieved by clicking the boards into position without the need for messy adhesives. Sun Floors laminate floors can be installed atop any level, dry, clean and sound surface, including existing hard floor coverings. An expansion gap needs to be left, during the installation of the floor, to the entire floor perimeter, allowing the floor to expand or contract (as one sheet or “raft”) across the subfloor in line with seasonal variations in relative humidity. A successful installation will rely heavily on strict adherence to these installation instructions. It is important to note that the two most common causes of floor failure or client dissatisfaction are installations over uneven subfloors and installations that do not provide sufficient perimeter expansion. It is also important to note that the Uniclic joining system allows for most boards to be installed without the need for a hammer and tapping block, however, some boards may need to be tapped together when fitting boards into profiles or installing around door frames. Care should be taken to ensure that the Uniclic tapping block is used when tapping boards into position.

PREPARATION

1.WHAT YOU’LL NEED TO INSTALL YOUR SUN FLOORS LAMINATE FLOOR

Apart from that, you will of course need your Sunfloors Laminate flooring, enough Sunfloors approved underlay, trims and profiles to finish the edges of your floor and a Maintenance Kit to ensure your floor looks it’s best after you’ve finished the installation. It is important to note that the Sun floors accessories have been specifically designed to provide optimal results for your floor and that using other products may cause damage to your floor. We advise to use only Sun Floors accessories with Sunfloors floors.

2.INSTALLATION PREPARATION

- It’s a good idea to bring the packs to room temperature prior to installation by stacking them in the room for up to 24 hours prior, particularly where the packs have been stored in especially hot or cold locations in the hours prior to installation. If storing packs on site, ensure they are stacked on pallets or similar, to keep them off the subfloor until installation.

- Remove all existing carpet or soft flooring and underlays. Sun Floors Laminate can be installed directly atop most existing hard flooring (ceramics, vinyl etc) but only when the existing flooring is well stuck and meets the criteria below for levelness, moisture content etc.

- Prepare the subfloor by ensuring that

All subfloors need to be;

- Sound and structurally stable enough to be installed atop. Any loose parts of the subfloor or hard flooring need to be secured, repaired or removed and replaced.

- Flat with no unevenness greater than 2mm over the length of 1 meter in any direction. This should be measured using a 1 metre long straightedge and no part of the subfloor surface should deviate more than 2mm from the underside (middle) of the straightedge. Should deviation greater than 2mm exist, concrete subfloors can be ground flat for filled / levelled using a self-levelling/smoothing compound like Ardur K15. Timber subfloors can be sanded flat, filled with an appropriate filling medium or sheeted with a suitable underlay to render them flat and stable.

- Clean and free of old adhesives, building rubble etc prior to installation.

Concrete subfloors need to be;

- Dry enough to install atop. Concrete floors should be tested using a hygrometer with a reading lower than 80% deemed dry. Three tests should be conducted for the first 50m² of any installation and one additional test per 50m² thereafter. In the instance that a subfloor is obviously or knowingly wet (insufficiently dry), it is always best to remedy the cause of the excessive moisture first. Installation can then be undertaken by first installing black 200uM builders plastic sheeting to provide a cost effective moisture vapour barrier. If installing black plastic sheeting, ensure to install the plastic sheeting up all vertical surfaces to create a “well’ and remember to overlap all joins by 600mm and tape all joins using a vapour tight tape.

Timber subfloors need to be;

- Dry enough to install atop. Timber floors should be tested using a pin probe style, penetrative electrical resistance meter with a reading lower than 12% in Southern States like Victoria or 14% in areas like North Queensland or Auckland deemed dry. It is important to allow for species calibration from an electrical resistance meter. Three tests should be conducted for the first 50m² of any installation and one additional test per 50m² thereafter. In the instance that a subfloor is obviously or knowingly wet (insufficiently dry), it is imperative to remedy the cause of the excessive moisture prior to installation.

- It is important that timber subfloors have sufficient cross flow ventilation in the crawl space under the subfloor with unblocked vents on all four sides of the building. Inspection of the crawl space is recommended prior to installation with damp smells or puddles of water in any area to be considered red flags that require further investigation.

3.CHECK THE DELIVERED GOODS

Packs should be checked on arrival to site to ensure that they are the correct product and colour and that they are free of damage. Damage to any packs should be reported to your place of purchase immediately. If storing packs on site for longer than 12 hours they should be stored flat and off the ground in a dry, well ventilated and safe place. The underlay delivered should also be checked on arrival. Ensure that your underlay is the recommended underlay as results or performance cannot be guaranteed on underlays other than Sun Floors Combi-Lay. If you have any questions at all, please consult your place of purchase.

It is recommended that you know how the trims and profiles to be installed with your flooring are installed as some profile bases are best installed prior to installing your floor. If you are in doubt, again please contact your place of purchase prior to installation.

Always install flooring in well-lit areas / conditions to ensure boards with visible faults are not installed.

4.SELECTING THE INSTALLATION DIRECTION

Sun Floors laminate floors will look and generally perform better when installed along the length of an installation area. Another consideration is the direction of natural light, with installations looking better parallel to the source of incoming light.

5.COMPARTMENTALISATION

In large or multi-room installations, you might need to install trims at door thresholds or throughout the installation area. This is known as compartmentalization. Check with your place of purchase prior to installation whether the area to be installed needs to be compartmentalised and for more information on the recommended location of in-floor trims.

6.FINALLY…

- Check that the doors can still open and close after the floor and underlay have been installed.

- Kitchen island benches and cabinets or any heavy fixtures should be installed prior to the installation of flooring and should not be installed atop laminate flooring. The floor must be able to move freely around any heavy objects to avoid bubbling of the floor, open joints and separating planks.

- Laminate flooring should not be installed externally or in areas that cannot reasonably be protected from the extreme temperatures or conditions. Sauna’s, sunrooms, commercial kitchens etc are considered unsuitable for laminate flooring.

- Any questions prior to or during the installation process should be directed to your place of purchase. It is always advised to seek advice before continuing with installation of flooring.

INSTALLATION

Sun Floors Laminate floors with hydroseal technology offer a waterproof surface warranty after installation that will range in term depending on the product purchased. Following these instructions carefully makes your Sun Floors Laminate floor fit for use in bathrooms, kitchens, laundry rooms and entrance areas as well as almost all other areas in the home or office. The panels are not suitable for use in damp spaces like pool areas, saunas and rooms with built-in drains like showers. Despite their waterproof surface, these floors may not comply with some regulations for waterproofing in wet rooms.

With Uniclic® panels you can choose where you want to begin…. Just think about the easiest way to install the floor. We will demonstrate the installation for right-handed people, from left to right. You can work in the other direction if you like.

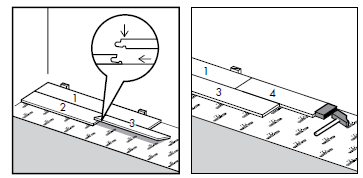

Uniclic® is unique because you can install the planks in two different ways. Method A: Position the panel to be installed at an angle of 20 to 30° to the panel already installed. Move the panel gently up and down and at the same time exert forward pressure. The panels will click into place with sufficient forward and downward pressure. You can either insert the tongue into the groove, or the groove on to the tongue. The tongue in groove method is the most common and easiest way. Method B: With Uniclic® you can also tap the panels into each other without lifting/ rotation. For this method you must use the special Uniclic® tapping block. The planks should not be joined with a single tap. To avoid damaging the panels you must tap them together gradually.

7.MIX THE PANELS

Make sure the panels are mixed sufficiently when you install them, so that you do not end up with too many identical, light or dark panels next to each other. To obtain the best visual effect, it is best to fit the floorboards in the direction of the longest wall and parallel to the incidence of light.

8.PLANNING AHEAD

It is more difficult to finish along walls using thin “slithers” of flooring as the final row and it looks better to avoid thin slithers on one side of a hallway. This said, measuring to see where boards will sit in the installation prior to installation can balance the floor aesthetically. Whilst this is not always possible or practical, it is best done prior to installation.

9.SKIRTING ON OR SKIRTING OFF

During the installation, an expansion gap will be left at the entire perimeter of the floor and where the flooring meets vertical finishes (skirting boards, walls, kitchen cabinets & kickboards, pipes etc). This gap will need to be covered after the installation has been completed. If skirtings have not been fitted, skirting boards usually cover this gap well for most installations. If you already have skirting boards and don’t want to remove and re-fit them, scotia profiles in matching colours are readily available from your Sun floors Retailer.

10.UNDERCUT DOOR FRAMES AND FIT PROFILE BASES

11.INSTALL THE UNDERLAY

Underlay is essential for all laminate installations. The specially designed Sun floors underlays have a damp-proof, insulating, noise-reducing and slight leveling function. The smooth top surface makes installing the laminate panels easier and allows the floors’ expansion afterwards.

12.INSTALL THE FIRST AND CONSECUTIVE ROWS

FINISHING

In rows where there is a pipe, make sure the pipe falls exactly in line with the short side of two panels. Take a drill bit with the same diameter as the pipe plus 20 mm (3/4”). Click the panels together on the short side and drill a hole centred on the joint between the two panels. Now you can install the panels.

In places where it is difficult to install the planks with the tapping block (e.g. underneath radiators), you can tap them together with the pulling iron and a hammer.

FINISHING IN ROOMS LIKE BATHROOMS, LAUNDRY ROOMS AND WET AREAS

MAINTENANCE

When moving heavy furniture back onto your floor or at any other time, ensure items are not dragged. If items are too heavy to be lifted, roll them carefully over a sheet of plywood that will protect the floor from damage.

In the case that your floor is exposed to potential stains, remove the staining agent as quickly as possible. If light rubbing with Cleaner is insufficient, acetone or nail polish remover can be used with a white cloth to assist stain removal. Never use scouring products! Never use wax or varnish coating on the floor.

.png)

Comments

Post a Comment